The denis cimaf mulcher operates as a robust machine designed for land-clearing operations, forestry work and vegetation management needs. The efficiency of this tool depends heavily on the type of blade knife used. Deciding on an appropriate blade proves essential to achieve maximum efficiency alongside enhanced durability and economic benefits. This guide will help you select your blade knife with all the necessary information.

Understand Your Mulching Needs

You should evaluate your cutting materials before choosing a blade knife. The blade specifications needed for different vegetation types and terrains must match. Ask yourself:

- The blade knife you need depends on whether you work with dense brush or thin vegetation.

- What type of blade do you require to work with rocky surfaces or soft ground?

- The conditions where you work will be wet or dry.

- The right blade selection for your job will make operations more efficient while extending blade resilience.

Consider the Blade Material

Blade components establish both their operational lifespan and their cutting performance qualities. The most common materials include:

- Tungsten Carbide-Tipped Blades

- Ideal for heavy-duty mulching.

The material provides excellent resistance to wear and maintains its longevity.

Hardened Steel Blades

- More affordable than carbide-tipped blades.

- The tool works well for clearing land from light to moderate conditions.

- Requires more frequent sharpening.

Alloy Steel Blades (42CrMo)

- It offers a balance between durability and flexibility.

- Provides high-impact resistance.

- The tool shows effective performance across different land-clearing operations.

Blade Design and Shape

The blade knife's cutting efficiency depends on its blade shape and design. Common options include:

Straight Blades

- Provide precise and even cuts.

- Best for softwood and uniform vegetation.

Curved Blades

- Upper material wattage increases when a blade manipulates material toward its center.

- Ideal for dense brush and hardwood.

Double-Sided Blades

- The blade can operate in reverse position to extend its operational time.

- Reduce downtime and increase efficiency.

Compatibility with Your Denis Cimaf Mulcher

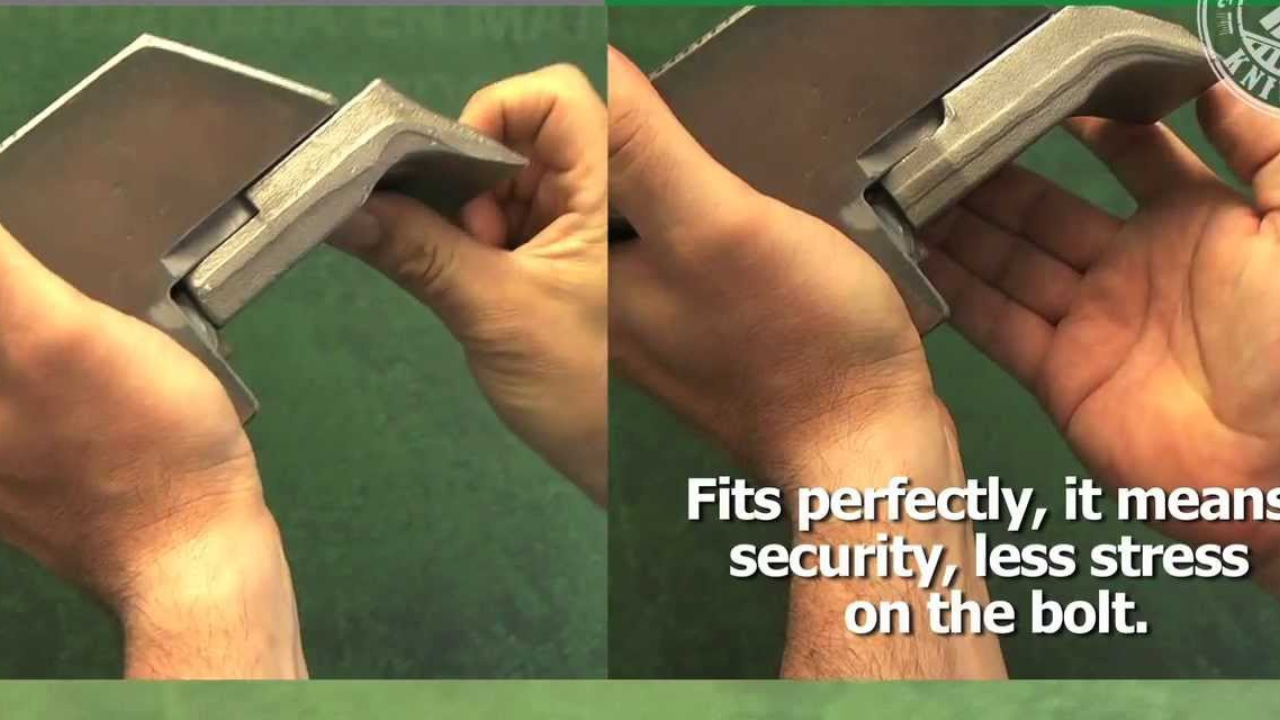

The blade selection depends on the specific model of the Denis Cimaf mulcher. Check the blade compatibility with your particular Denis Cimaf machine through a verification process of bolt patterns, mounting holes, blade length, thickness, and manufacturer specifications.

Hard-Facing and Coating for Extended Life

The application of hard-facing technology creates an extra protective layer that extends the blade's operational life. Some coatings to consider:

- Chromium (CR-W) coating will provide abrasion resistance.

- Carbide Hard-Facing technology provides two benefits: it decreases blade wear and makes blades last longer.

- Such treatments applied to blades decrease both maintenance expenses and boost operational efficiency.

Consider Cost vs. Longevity

Carbide-tipped blades cost more initially but provide longer product lifetimes than steel blades, so businesses will save money on replacements in the future. The purchase of premium blades results in decreased replacement expenses and operational interruptions.

Regular Maintenance for Best Performance

Blade efficiency, along with lifespan, reaches maximum levels through these implementation methods:

- Regular blade sharpening extends their cutting efficiency.

- Clear blades immediately after use to stop both rust formation and substance accumulation.

- Regular inspections should identify damaged blades that need immediate replacement before blades become too worn.

Conclusion

The blade knife selection for your Denis Cimaf mulcher requires consideration of your operational requirements and environmental conditions as well as financial resources. The selection of material and design alongside compatibility checks will lead to optimal performance. High-quality blade investments improve both operational efficiency and increase the lifespan of your mulcher equipment, which leads to more productive land-clearing operations.